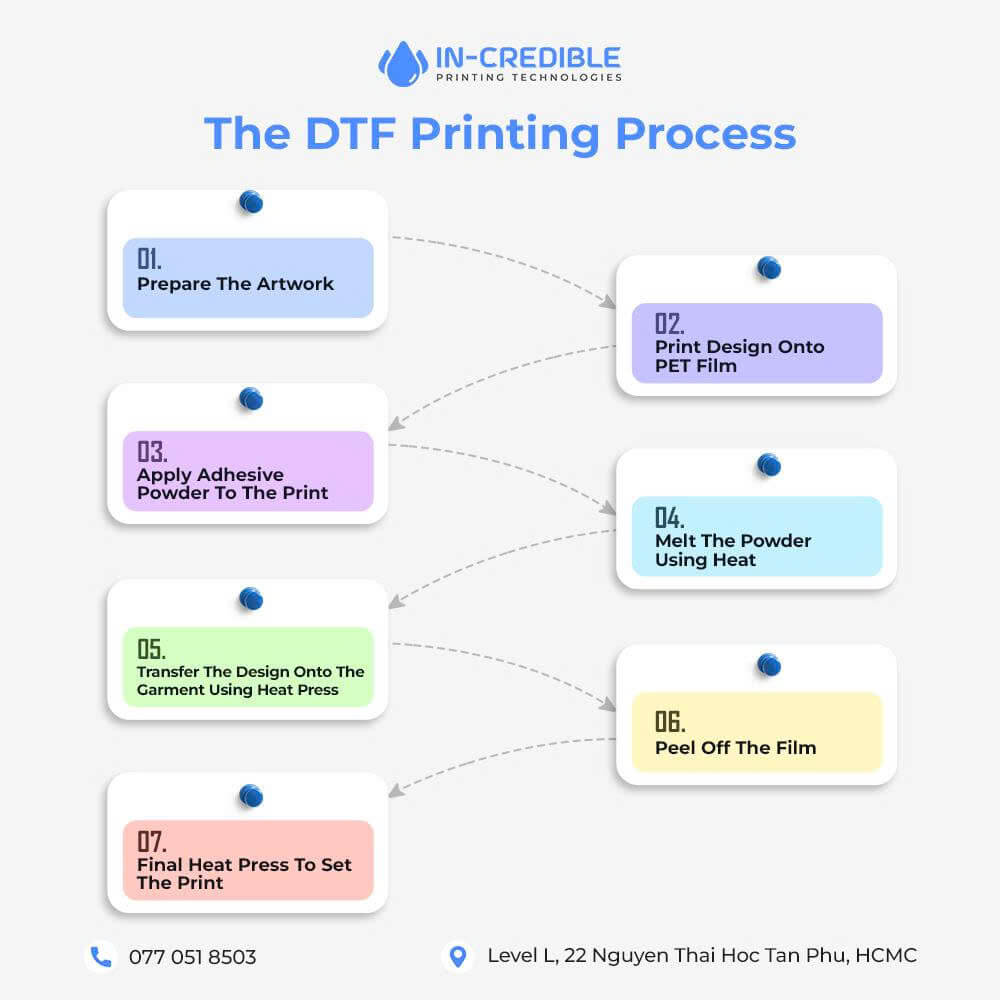

In the fast-paced world of custom apparel and textile decoration, staying ahead means embracing technology that delivers both quality and efficiency. High-volume Direct-to-Film (DTF) printing is that game-changing technology. Moving beyond the limitations of traditional methods like screen printing and even older digital techniques, DTF has emerged as a powerhouse for producing vibrant, durable, and highly detailed designs at scale. Understanding the DTF printing manufacturing steps is crucial. It ensures quality, efficiency, and sustainability.

This guide aims to demystify the DTF production process. Whether you are a start-up, entrepreneur, or a garment industry, this guide will help you. We will walk you through the essential manufacturing steps in DTF printing. From design to delivery, each step matters. Knowing these steps ensures your business operates at peak performance. It also helps in troubleshooting and improving processes.

Design Preparation & RIP Software Management

The journey of every DTF print begins on a computer screen. High-volume production demands more than just a creative design; it requires a print-ready file. This step involves using specialized software, often referred to as Raster Image Processor (RIP) software, to prepare the artwork.

Artwork Requirements

Your design files should be high-resolution (at least 300 DPI) and have a transparent background. A common practice in DTF printing is creating “gang sheets,” which involves arranging multiple designs on a single roll of film. This is a critical step for maximizing film usage and minimizing waste, a key consideration for high-volume DTF printing operations.

RIP Software's Role

In modern garment production, software plays a significant role. The RIP software is the brain of the operation. It manages color profiles, ensures precise color reproduction, and creates the white ink underbase layer. This underbase is what allows DTF prints to be so vibrant and opaque, even on dark fabrics. The software also controls the printer’s settings, ensuring the right amount of ink and powder is used for each job, a crucial detail for maintaining consistency in industrial DTF printing.

Choosing the Type of Materials

Sourcing raw materials is a fundamental step in DTF production. The choice of materials affects the garment’s quality, feel, and durability. DTF printing is suitable for variety of fabric, include cotton, polyester, nylon, and blends. DTF printing can also be applied to fabrics such as silk, denim, and even leather.

- Cotton: providing durability and vibrant colors.

- Polyester: is another popular choice, especially when printing on sportswear or stretchy clothing.

- Nylon: often used in products such as handbags, backpacks, or workwear.

- Blends: such as cotton-poly, providing a combination of softness and durability.

- Silk: is luxurious, smooth, and lightweight. It is perfect for high-end fashion.

- Denim Fabric: is a thick and durable fabric, which can be DTF printed to create unique fashion products.

- Leather Fabric: handbags, wallets, or leather clothing, giving a luxurious and modern look.

The Printing and Powdering Process

Once the digital design and materials are ready, the physical DTF manufacturing process begins. This step involves a large-format DTF printer that prints the design onto a special PET film. This is a different kind of film than what is used in screen printing, engineered specifically for DTF printing technology.

Printing the Design

Applying the Adhesive Powder

Immediately after the ink is laid down, while it is still wet, a hot-melt adhesive powder is applied. In a high-volume setting, this is typically done by an automated shaker unit. This unit ensures a perfectly even coating of powder across the wet ink and shakes off any excess. This step is a cornerstone of the DTF production steps, as the adhesive powder is what will eventually bond the ink to the garment.

Curing the Film

Melting the Adhesive

Temperature and Time

The Heat Transfer to the Fabric

This is where the magic happens and the design is brought to life on the textile.

The first phrase of this step is Pre-pressing the fabric. The fabric, usually is T-shirt, is first placed on a heat press and pre-pressed for a few seconds. This action helps remove any moisture and wrinkles, creating a perfectly flat surface for the transfer.

Next, we will apply the DTF print to the fabric. The cured DTF film is placed on the garment. The heat press is activated, applying a combination of heat and pressure to the transfer. This heat activates the adhesive layer, causing it to melt and bond with the fibers of the fabric.

Finally, we are going to peel the film. After a specified time, the press opens, and the garment is removed. Depending on the type of film used (hot-peel or cold-peel), the film is carefully peeled away, revealing the finished, vibrant design. This is one of the most satisfying DTF production steps to witness.

Quality Control and Finishing

No industrial DTF printing operation is complete without a robust quality control process.

Inspection: Each finished garment should be inspected for print quality, alignment, and any imperfections. High-volume DTF printing requires a keen eye for detail to ensure every piece meets the brand’s standards.

Post-pressing: For added durability and a softer feel, many manufacturers do a second, shorter press with a Teflon sheet. This helps the print meld further into the fabric, making the final product more comfortable and long-lasting.

The Advantages of High-Volume DTF Printing

There are 3 key advantages of this printing method.

First is versatility. DTF works on a wide range of fabrics, including cotton, polyester, and their blends, making it an incredibly versatile solution for diverse product lines.

The second advantage is durability. Properly produced DTF prints are known for their exceptional durability. They resist cracking, fading, and peeling, even after multiple washes, making them perfect for activewear and everyday apparel.

And last but not least, its vibrant colors. The white underbase allows for prints with vivid, opaque colors that stand out on any color fabric, especially dark materials where other printing methods struggle.

Conclusion

High-volume DTF printing is more than just a technique, it’s a strategic decision for manufacturers looking to streamline their production and deliver high-quality, durable, and vibrant products. By mastering the DTF manufacturing process, from meticulous design preparation to the final quality check, you can unlock new levels of efficiency and flexibility. Embracing this DTF printing technology is not just about keeping up with the competition, it’s about leading the way in the future of textile decoration.

Ready to start your next bulk order? Reach out to In-Credible for an innovative and reliable partner in DTF printing in Vietnam.